IE450

Classification:

- Product Description

- Technical Parameter

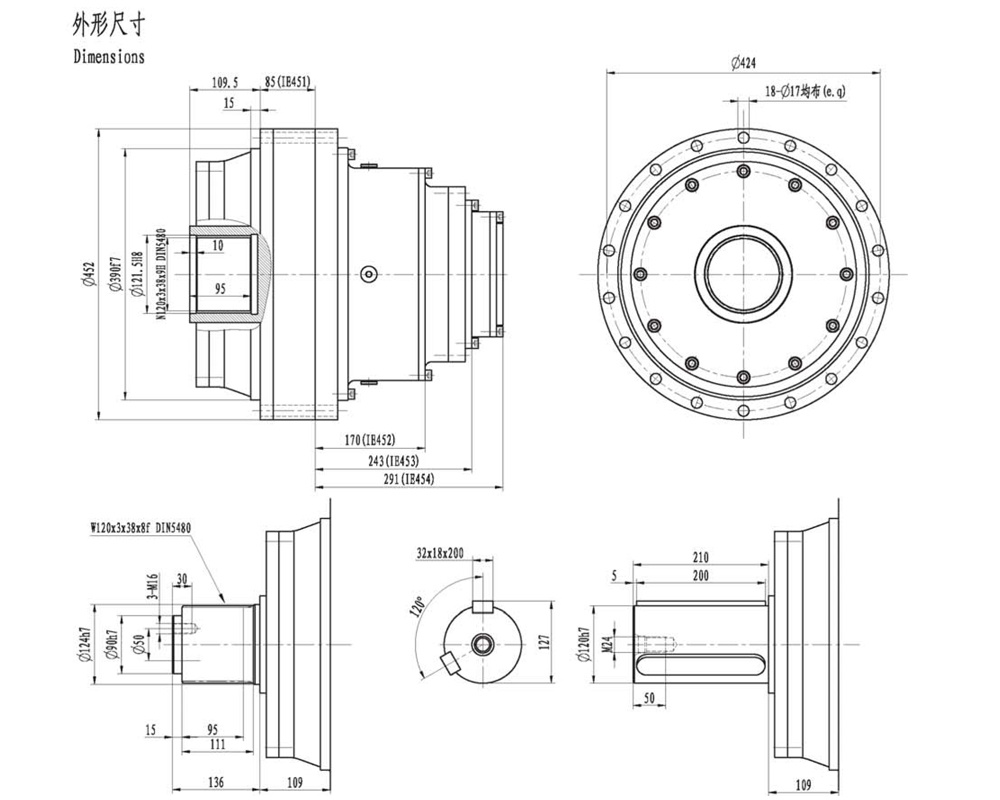

- Installation Dimensions

- Application fields and cases

-

1. Overview

IE series planetary reducer is composed of multistage planetary transmission. It has the characteristics of small radial size, modular design, large output torque, various output shaft forms, high transmission efficiency, low noise, and good economy. Therefore, it is widely used in construction engineering, railway, highway, ship, petroleum, coal mine, metallurgy and other machinery. According to different needs, users can choose different types of hydraulic motors or motors as driving components.

2. Model description

3. Model examples

IE613-N110IAR indicates that the maximum radial size of the planetary reducer is 610mm, the use of 3-stage planetary transmission, with a brake, the reduction ratio is 110, the output shaft is in the form of an involute spline, and the radial hydraulic motor.

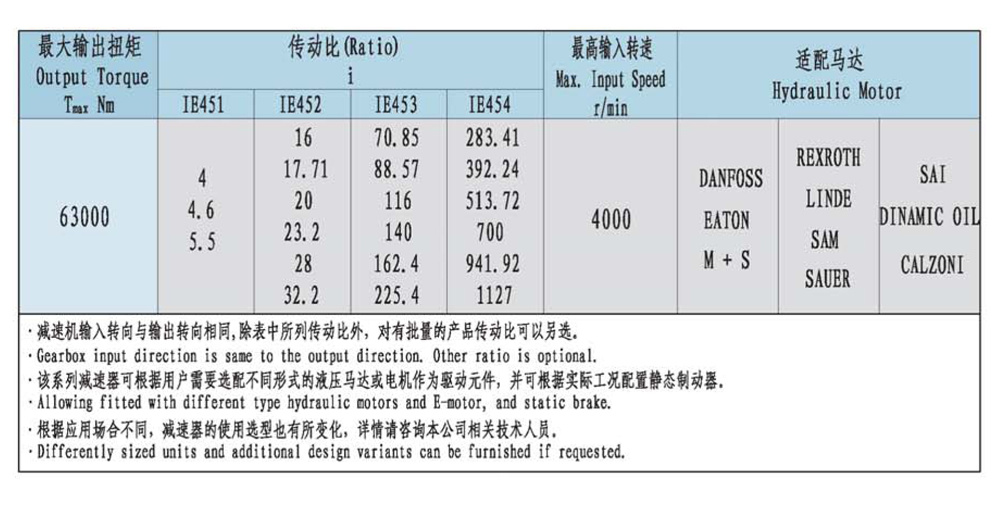

4. Technical description

1) The reducer can be accompanied by a hydraulic static brake;

2) The selection of the reducer should consider the requirements of safety factor grade, FEM grade and service life;

3) This type of reducer is not suitable for bearing large radial load, generally only used to transfer torque, installation and operation must check whether the output shaft is compressed and bent;

4) The choice of lubricating oil for the reducer must be selected according to the environment and working temperature of the reducer. The reducer must be replaced once after 150-200 hours of trial operation, and then according to the working condition of the gearbox, the oil must be changed after 2000-4000 hours of operation, and it must be replaced at least once a year. When changing the oil, in order to facilitate the emptying of the lubricating oil in the reducer, it is recommended that the lubricating oil be replaced when it is warm;

5) The recommended operating temperature of the standard reducer is -15℃- +40℃.

-

-

Related Products

Product Consulting

For more information of interest, please fill in the form below and we will contact you as soon as possible.

Service hotline: 86-057486300164

(Monday to Friday 9:00-17:00)

Service Hotline:

Address: No. 288, Batou West Road, Beilun District, Ningbo City, Zhejiang Province

Fax:+86 574 8611508

© 2024 YINING Hydraulic Co., LTD. All rights reserved